In today’s fast-paced world, businesses are constantly seeking innovative ways to boost efficiency and productivity. Robotic automation has emerged as a game-changer, revolutionizing industries by streamlining processes and reducing manual labor. However, as with any transformative technology, it comes with its share of questions and uncertainties. In this article, we will dive deep into the frequently asked questions (FAQs) surrounding robotic automation to provide you with a clear understanding of its applications and benefits.

1. What is Robotic Automation?

Robotic automation, often referred to as industrial automation, is the use of robots and computer programs to perform tasks with minimal human intervention. These tasks can range from simple, repetitive actions to complex processes that require precision and accuracy.

2. How Does Robotic Automation Work?

Robotic automation systems are equipped with sensors, actuators, and control software that allow them to interact with their environment. They can be programmed to follow predefined instructions, making them capable of tasks like assembly, welding, pick-and-place, and quality control.

3. What Industries Benefit Most from Robotic Automation?

Robotic automation finds applications across various industries, including manufacturing, healthcare, agriculture, logistics, and more. Manufacturers use robots for mass production, while healthcare facilities rely on them for surgery and patient care.

4. What Are the Key Advantages of Robotic Automation?

The benefits of robotic automation include increased efficiency, improved quality, reduced labor costs, and enhanced safety. Robots can work 24/7 without fatigue and are highly precise, leading to fewer errors.

5. Are There Any Disadvantages to Robotic Automation?

While robotic automation offers numerous advantages, it can also be expensive to implement initially. Additionally, some tasks may still require human intervention, and there is a learning curve associated with operating and maintaining robotic systems.

6. How Can I Implement Robotic Automation in My Business?

Implementing robotic automation involves assessing your specific needs, selecting the right type of robots, and integrating them into your existing processes. Collaborating with experts in automation can streamline this process.

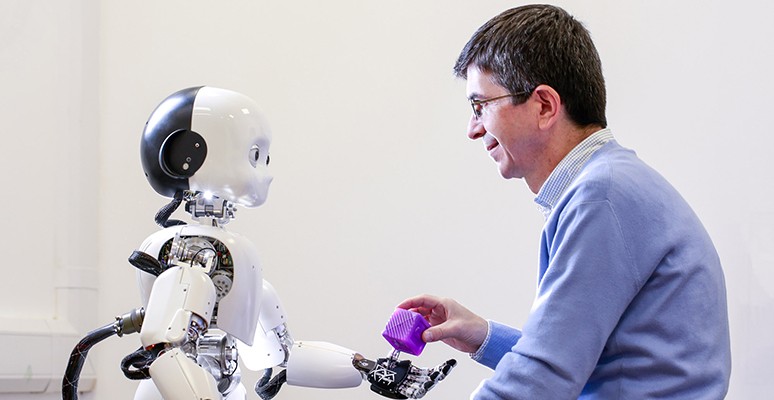

7. What Types of Robots Are Used in Automation?

There are various types of robots used in automation, including industrial robots, collaborative robots (cobots), and autonomous mobile robots (AMRs). Each type has its own set of capabilities and applications.

8. Is Robotic Automation Safe for Workers?

Robotic automation is designed with safety in mind. Collaborative robots, in particular, are built to work alongside humans safely. Proper training and safety protocols are essential to ensure a secure working environment.

9. What Costs Are Associated with Robotic Automation?

The costs of robotic automation depend on factors like the complexity of the system, the type of robots used, and the scale of implementation. While there are initial costs, the long-term benefits often outweigh them.

10. How Can I Ensure a Smooth Transition to Robotic Automation?

A smooth transition to robotic automation involves thorough planning, employee training, and ongoing support. It’s essential to involve your workforce in the transition and address any concerns they may have.

11. What Is the Future of Robotic Automation?

The future of robotic automation looks promising, with advancements in artificial intelligence and robotics. We can expect to see even more sophisticated robots capable of handling a wider range of tasks.

12. Can Small Businesses Benefit from Robotic Automation?

Yes, small businesses can benefit from robotic automation by automating repetitive tasks, reducing labor costs, and increasing production efficiency.

13. Are There Any Environmental Benefits to Robotic Automation?

Robotic automation can lead to environmental benefits by reducing waste, energy consumption, and emissions. It promotes sustainable practices in manufacturing and other industries.

14. How Does Robotic Automation Impact Job Roles?

Robotic automation may change the nature of certain job roles, but it also creates new opportunities in fields like robotics engineering and maintenance.

15. What Are Some Success Stories of Robotic Automation?

Several companies have experienced significant success with robotic automation, such as automating car manufacturing, improving healthcare procedures, and enhancing logistics operations.

Conclusion

Robotic automation is transforming industries and reshaping the way we work. By addressing these FAQs, we hope to have demystified this technology and provided you with valuable insights. Embracing robotic automation can lead to increased efficiency, competitiveness, and sustainability for your business.